Decisive for the use of a certain spray head is, in addition to the correct area of application, in particular also its installation situation. In many cases, the space conditions, the supply direction for the air and liquid or the ambient temperature are crucial. Over the last decades, we have developed numerous different spray heads for a wide range of requirements.

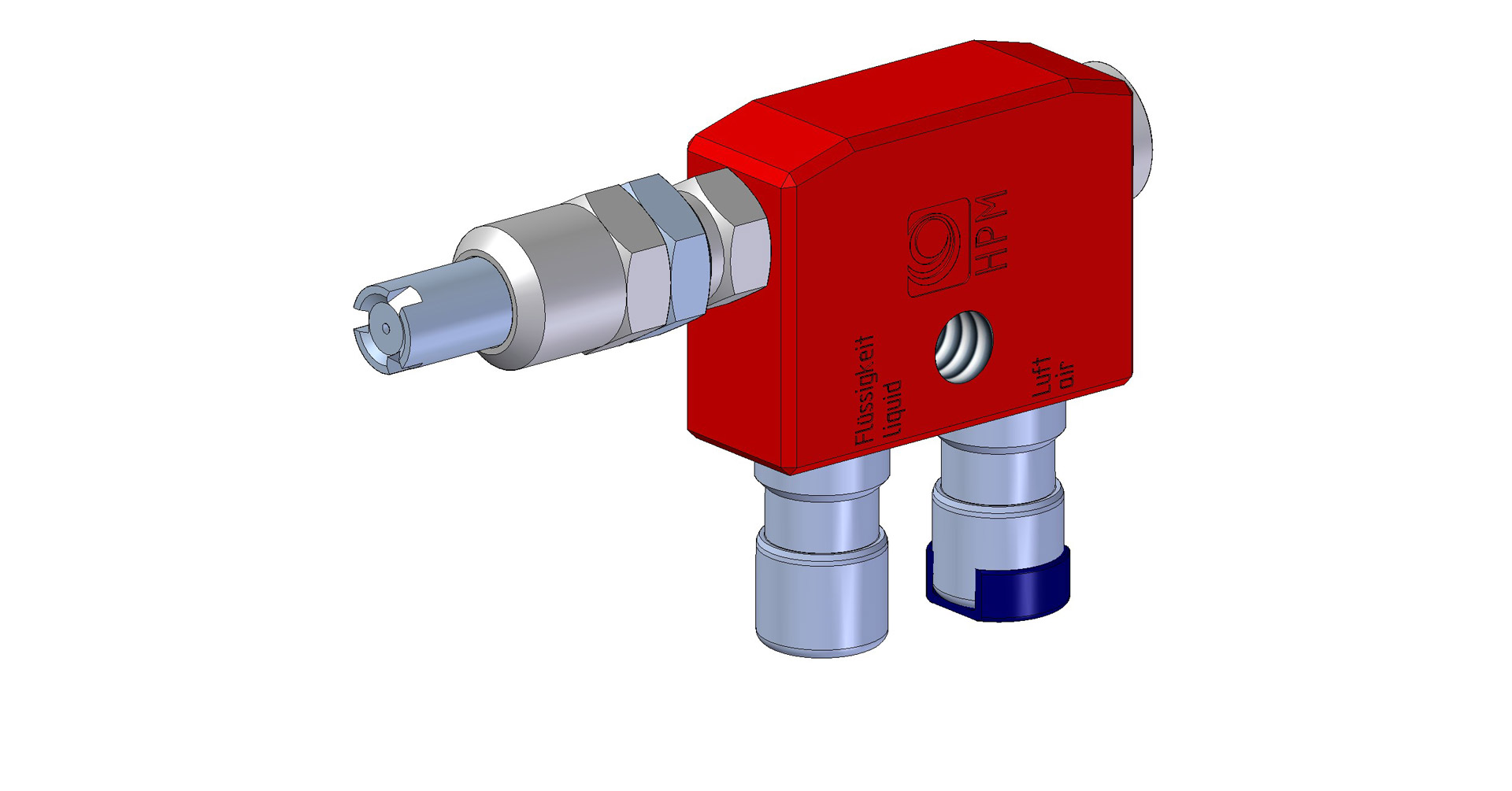

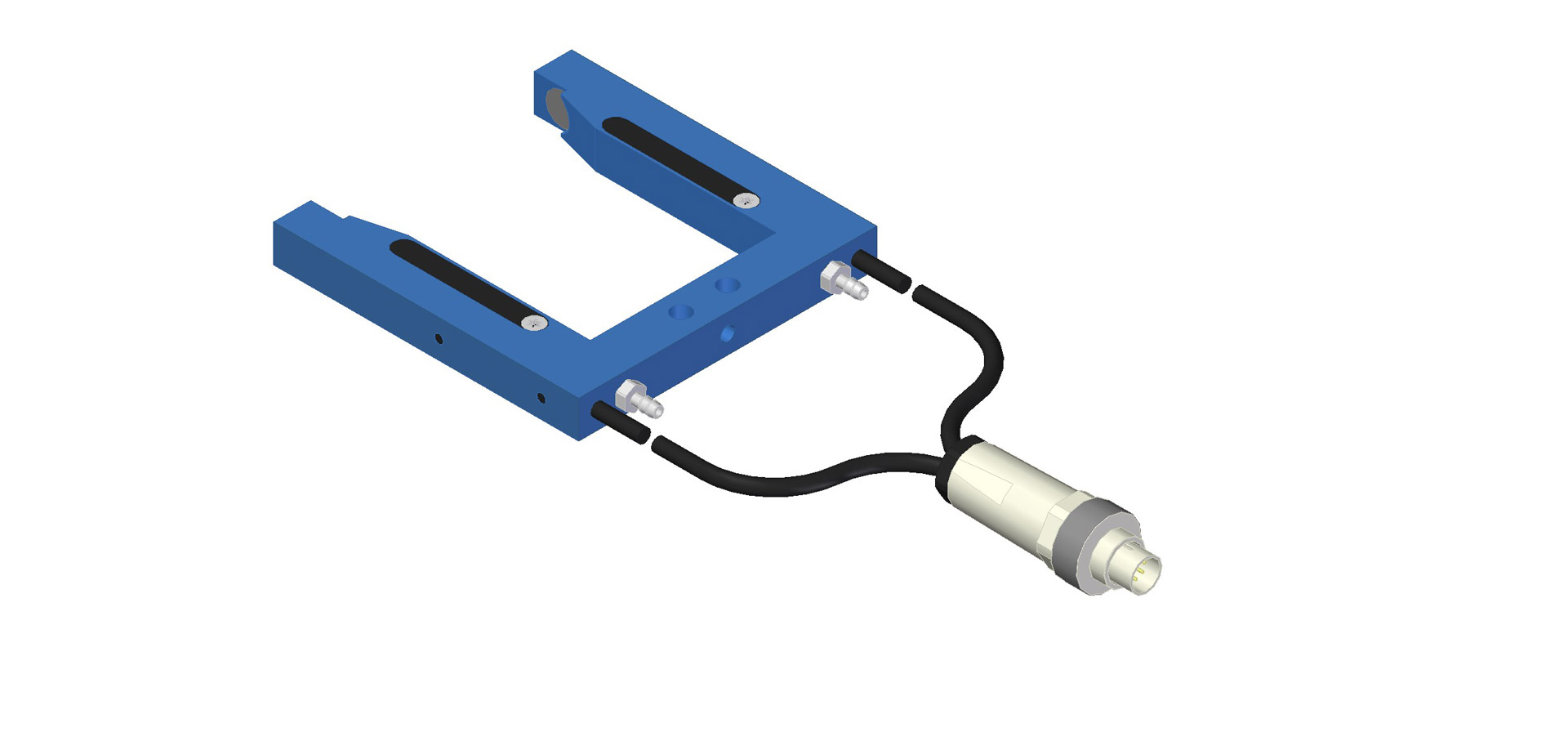

HPM round jet nozzle

With the HPM round jet nozzle in combination with a spray head of the LEO series we solve a specific customer problem. The task was to wet pipes evenly and constantly from the inside with lubricant. This could not be solved satisfactorily with a conventional spray head. With the development of the round jet nozzle, we have now developed a possibility to solve this task perfectly.

A spray head of the LEO series is coupled with the newly developed round jet nozzle. The insertion depth is determined by the spray head (see LEO series). Other lengths are available on request.

Due to the separation of spray head and nozzle we are able to keep the round jet nozzle very maintenance friendly. In case of blockages, the nozzle is simply removed and cleaned. The application possibilities are almost unlimited. Be it for corrosion protection or for internal forming. Both the depth and the tube diameter are irrelevant.

With the round jet nozzle from HPM you always have the best solution for your process.

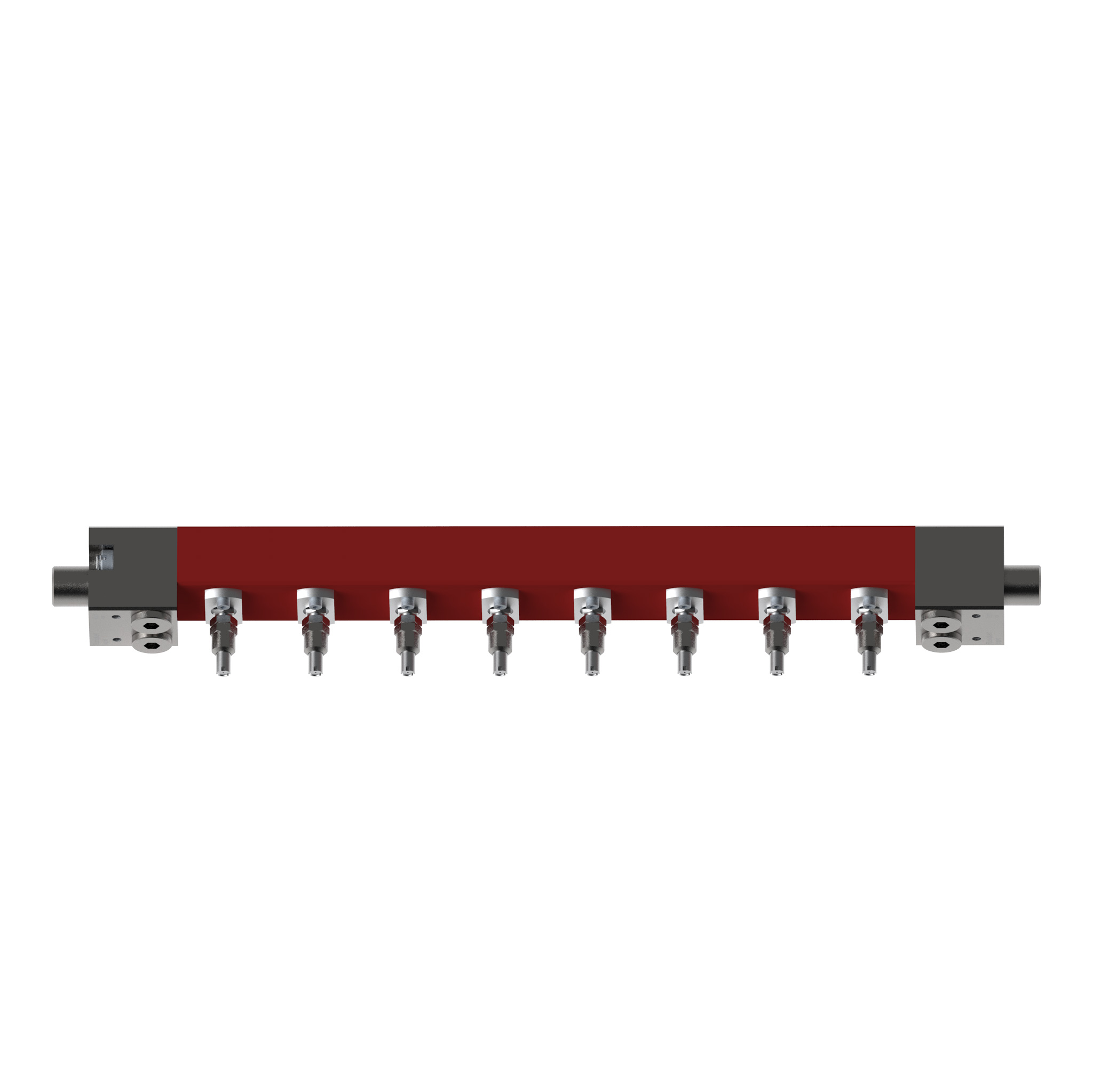

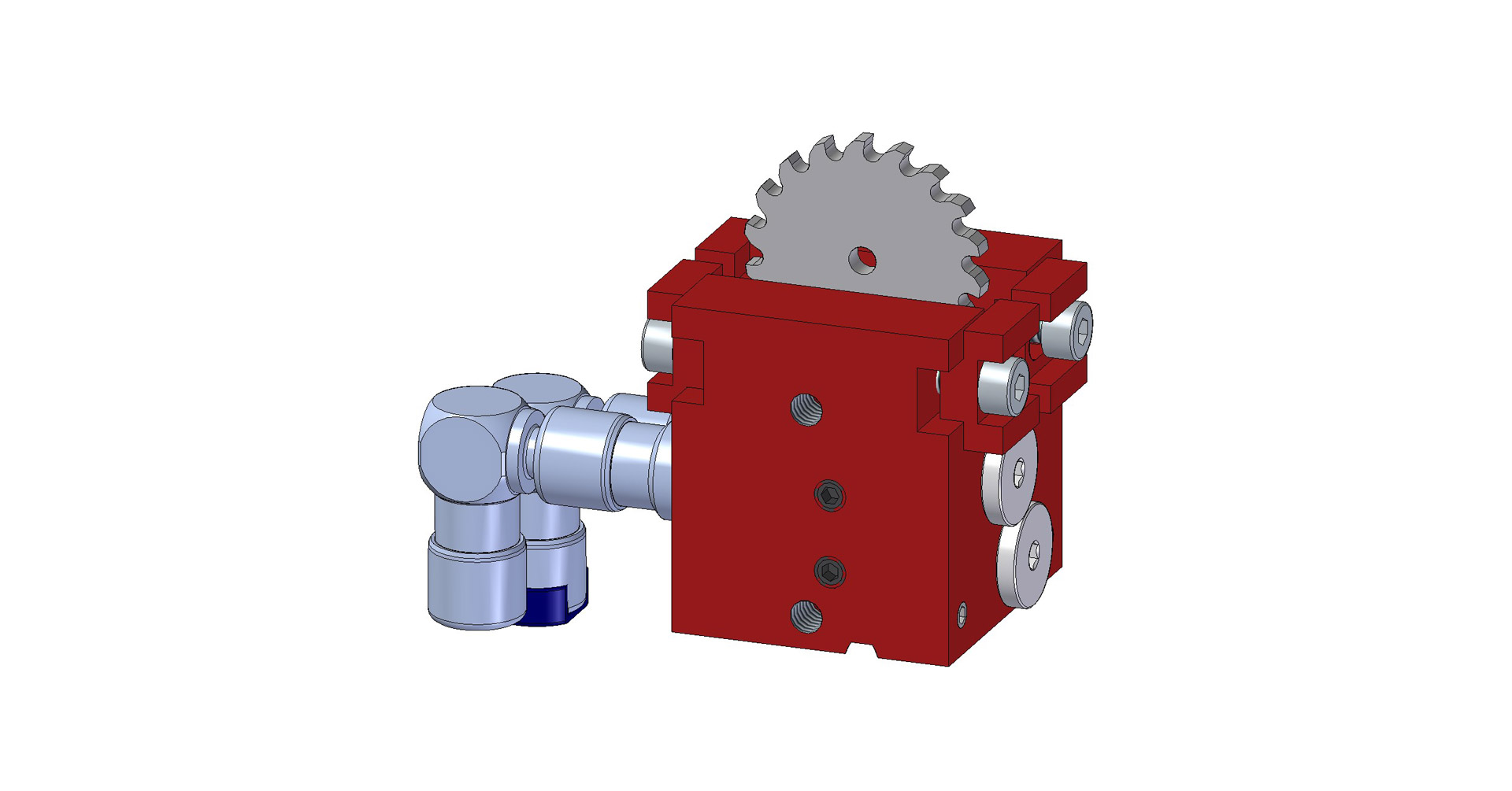

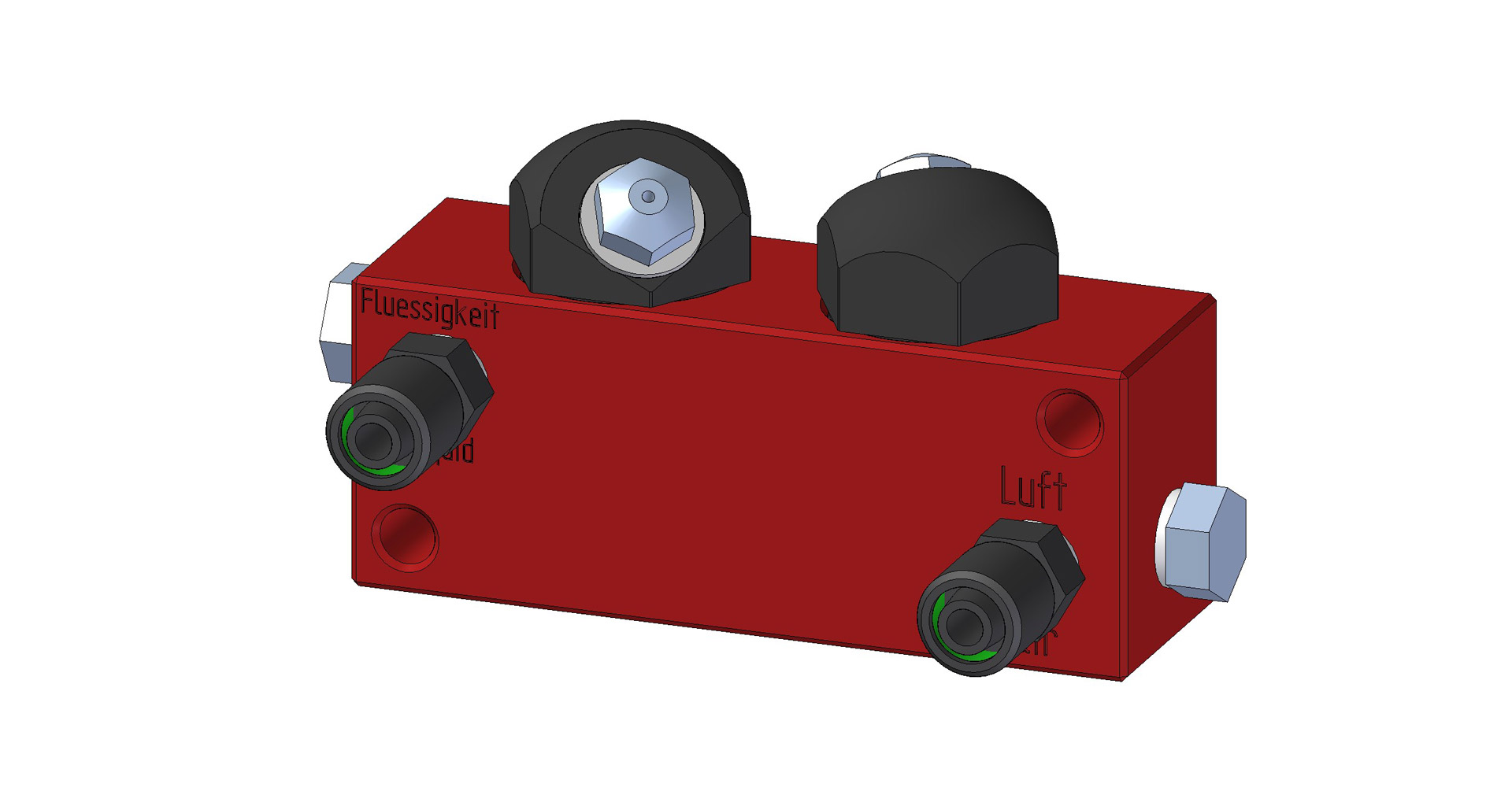

Spray head PSM 3-fold

A 3-point spray head developed specially for sawing. The advantage of this spray head is that the three optimally arranged spray nozzles interrupt the normally present air cushion of the fast rotating saw blade. As a result, the lubricant always optimally arrives at the working position. Locking screws maintain the spray quantity that is set.

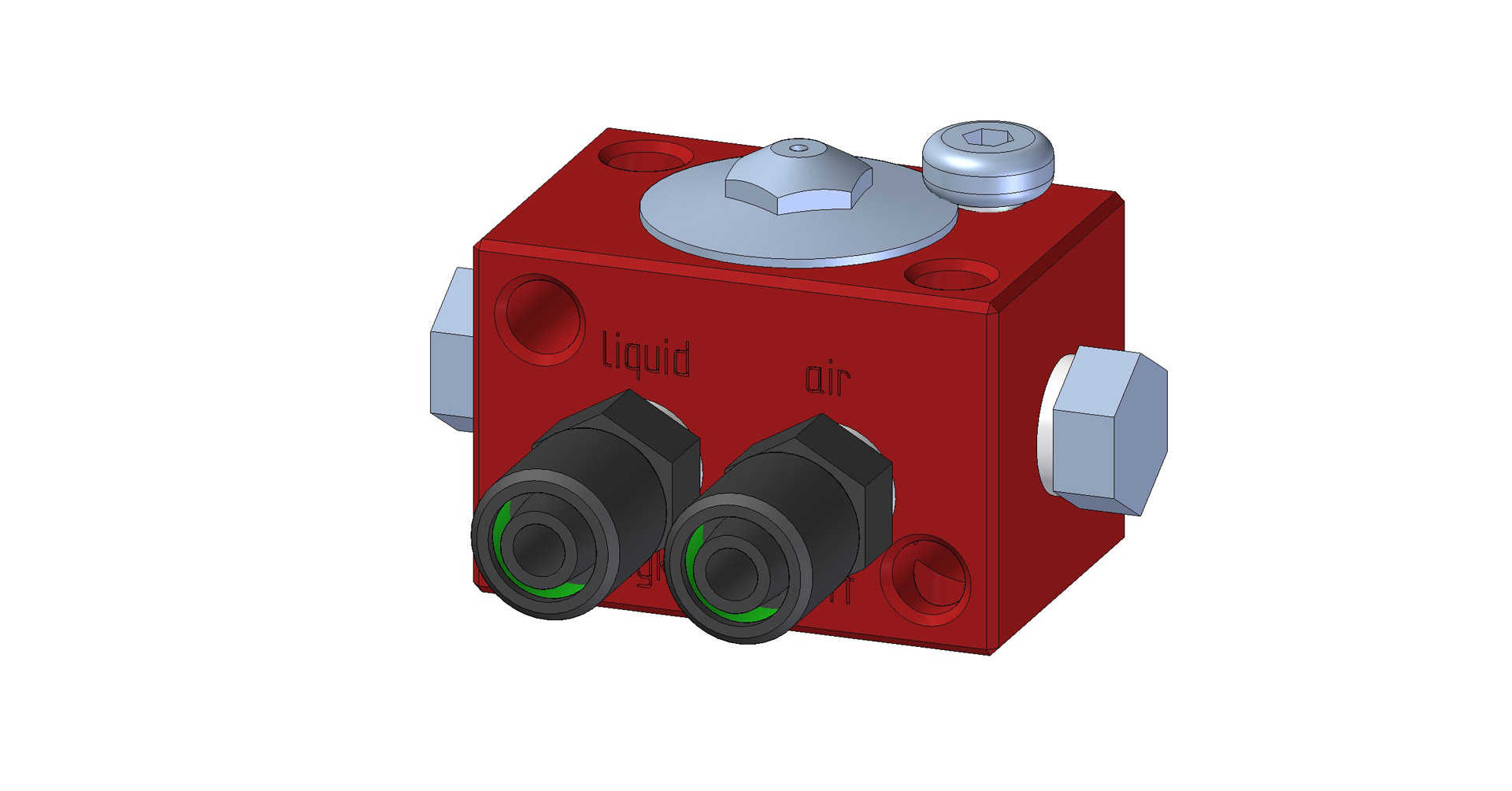

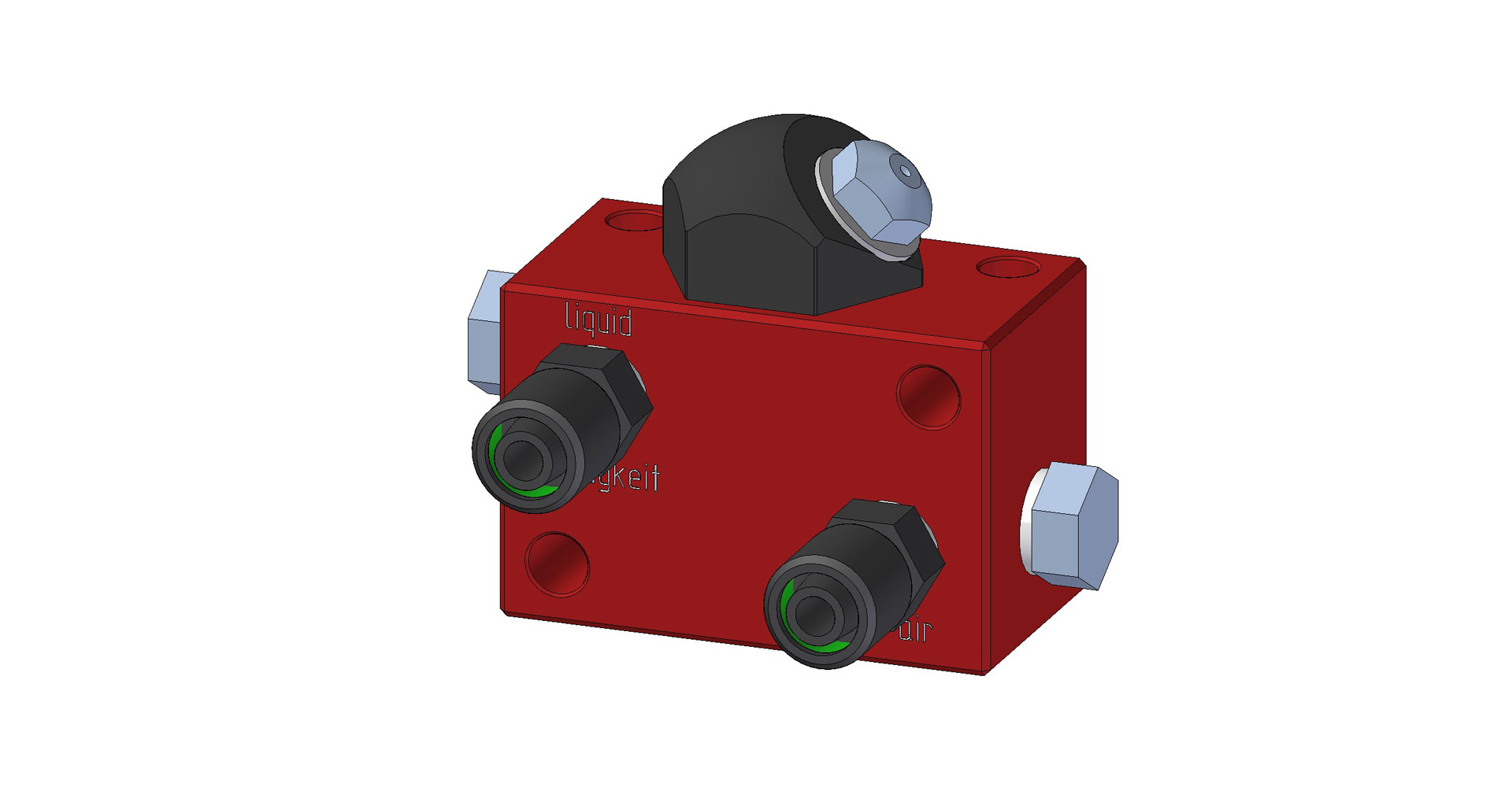

Spray head PBMJ

Small spray head for tight installation spaces. The quantity is set in the front at the spray jet outlet. The lines are mounted at a 90° angle or with a side exit. Due to the individual supply and the small diameters, this spray head is only suitable to a limited extent for viscous, strongly adhesive fluids.

Spray jet monitoring

Play it safe and monitor your process with our proven fork light barriers of the GD series. Their robust metal housing and high degree of protection are designed for demanding applications in mechanical engineering. The control electronics are integrated in the sensor housing.

Maximum security for your process