Efficient, Individual, Flexible, Precise.

The spray heads are designed for controlled and fine film application of fluids in the low-pressure range using the injection principle. This means a very economical air consumption of approx. 2 - 5.5 l/min. at the same time.

All fluids can be sprayed that have a maximum viscosity of approx. 2.300 mm²/s at 20° or 500 mm²/s at 40° (except for substances containing paint, resin and glue).

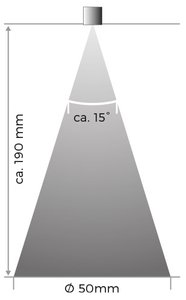

The spray head is set to a medium value at the factory. The spray jet produces a nearly full cone of approx. 15°. Depending on the fluid structure of the processing media used, the opening angle of the spray cone can be larger or smaller.

Ideally, the distance of the spray nozzle to workpiece/ tool to be sprayed should not be greater than 200 mm. An average spray cone of 15° covers an area of approx. Ø 50mm.

The output quantity with water is 0.04 litres to 4.2 litres per hour in continuous operation.

Viscosity & consumption values

Fluids with a viscosity of 100 mm2/s (20° C) up to 2300 mm2/s (20° C) can be sprayed with our spraying systems. We recommend usingSURVOS-, SENTOS- or SAMNOS- Fluids from HPM Technologie, which apply an even, fine film of the medium with sometimes absolutely residue-free drying (SURVOS) with very low consumption volumes

Spray head example

Air consumption per nozzle:

at 0,5 bar 2 l/min.

at 1,5 bar 4 l/min.

from 1,5 to 2,5 bar 5 l/min.

Consumption value with water:

from 0.04 to 4.2 l/h, depending on the nozzle combination. All nozzles achieve a full cone and a spray cone angle of approx. 15°, depending on the fluid structure.